You're knee-deep in your first real radio setup, connectors spread across the workbench like puzzle pieces, and then it hits you: one wrong move here means dead air or worse. Radio cables and connectors aren't forgiving. They'll expose every shortcut, every lazy assumption, every moment you thought "close enough" would cut it.

Picking the wrong cable ranks right up there with showing up to a black-tie event in cargo shorts. Coaxial cables aren't interchangeable widgets you grab off the shelf. RG-58 works fine for short VHF runs, but try pushing UHF signals through it over distance and you'll watch your signal attenuate faster than ice cream melts in July. RG-213 handles higher frequencies and longer distances, yet I've seen students blow their project budgets on expensive cable when cheaper options would've done the job perfectly.

Specifications matter more than most beginners realize. Impedance mismatches between your cable and equipment create standing wave ratios that'll make your transmitter work harder than it should, generating heat and potentially damaging components. Your 50-ohm transceiver doesn't play nice with 75-ohm cable, no matter how much you want it to. Velocity factor, capacitance per foot, attenuation ratings - these aren't just numbers to memorize for exams. They're the difference between a system that sings and one that whimpers.

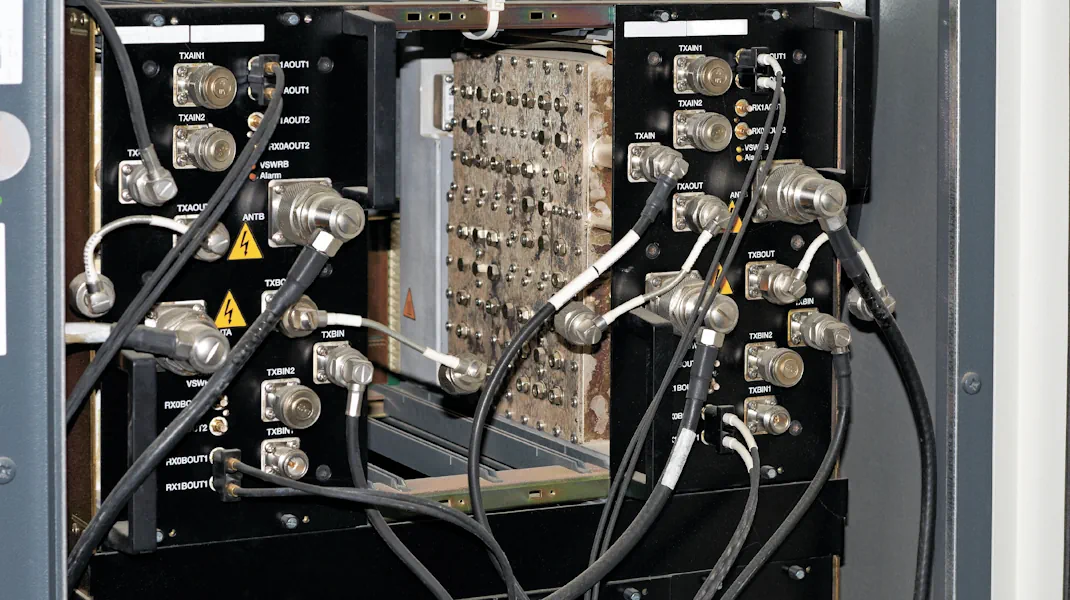

Connector incompatibility creates its own special brand of chaos. BNC connectors are ubiquitous in lab environments, N-type connectors handle higher power and frequencies, SMA connectors work beautifully for compact equipment. Mixing them requires adapters, and every adapter you add introduces loss and potential points of failure. I watched a classmate spend three hours troubleshooting a "broken" amplifier before realizing his hodgepodge of adapters had created enough loss to render the whole setup useless.

Gender confusion happens more than anyone wants to admit. Male and female connectors exist for reasons beyond keeping connector manufacturers employed. Planning your cable runs means understanding which end needs which gender, and ordering accordingly. Nothing quite matches the frustration of discovering you've crimped fifty connectors onto expensive cable, all the same gender, when you needed a mix.

Installation technique separates professionals from amateurs. Over-tightening connectors strips threads, under-tightening creates intermittent connections that'll drive you mad during troubleshooting. Torque wrenches exist for high-stakes installations, though most student projects don't require that level of precision. Hand-tight plus a quarter turn usually suffices, but develop a feel for it. Strip your first connector thread and you'll remember the lesson.

Crimping demands precision that borders on obsessive. Strip too much insulation and you've created a short waiting to happen. Strip too little and your crimp won't make proper contact with the conductor. The dielectric needs to sit flush against the connector body, the center conductor needs to protrude exactly the right amount, and the crimp itself needs uniform pressure around the circumference. Cheap crimping tools produce inconsistent results - this isn't the place to save fifteen bucks.

Soldering introduces even more variables into an already finicky process. Cold solder joints look decent but fail under vibration or thermal cycling. Too much heat damages the dielectric or deforms the connector body. Proper solder joints are shinier than a new penny, with smooth fillets that show complete wetting of both surfaces. Practice on scrap cable before tackling your project cables, because desoldering and starting over gets old fast.

Cable handling separates those who've learned from painful experience and those about to. Coaxial cable has a minimum bend radius - exceed it and you've crushed the dielectric, changed the impedance, and created a point of signal reflection. The cable jacket might look fine, but the damage lurks inside where you can't see it. Sharp kinks are obviously bad, but even gentle curves repeated in the same spot fatigue the cable over time.

Twisting cable while pulling it through conduit or around corners damages the braid and can separate the center conductor from the dielectric. The cable wants to lie flat and follow gentle curves. Fight that tendency and you're courting trouble. Strain relief at connectors isn't optional decoration - it's what keeps mechanical stress from being transmitted to your carefully prepared connection.

Environmental factors get overlooked until they've already caused problems. Standard PVC-jacketed cable deteriorates in sunlight faster than expectations crumble during finals week. UV exposure makes the jacket brittle, moisture infiltrates, corrosion begins its inexorable work. Outdoor installations demand UV-resistant jacketing or protective conduit. Direct burial cable exists for underground runs - regular cable buried in dirt won't last a season.

Temperature cycling expands and contracts materials at different rates. Connectors and cable don't always move in harmony, creating mechanical stress at the junction. Water intrusion into connectors creates corrosion that increases resistance and generates heat. Proper weatherproofing means more than wrapping connections in electrical tape. Self-amalgamating tape, heat-shrink with adhesive, proper drip loops - these techniques keep moisture where it belongs.

Maintenance schedules sound boring until a critical system fails during a demonstration or emergency. Connectors corrode, screws loosen, cables develop problems that visual inspection catches before they cause complete failure. A quick check every few months beats a panicked troubleshooting session when nothing works. Clean contacts with proper solvents, verify connections remain snug, look for signs of stress or damage.

Testing gets skipped more often than it should, usually right before Murphy's Law demonstrates why that was foolish. A simple continuity check verifies you haven't created an open circuit. Measuring DC resistance catches gross problems. But proper testing means using an SWR meter or vector network analyzer to verify your transmission line system performs as designed. A cable that shows continuity might still have significant loss due to damaged dielectric or poor connections.

Time domain reflectometry reveals faults in cable runs with precision. Send a pulse down the cable and measure the reflections - each impedance discontinuity shows up as a blip at a specific distance. This technique finds problems that would take hours to locate through trial and error. Not every student lab has a TDR, but knowing the technique exists and how it works makes you more employable.

Documentation falls into that category of tasks everyone knows they should do and almost nobody actually does. Label your cables. Record your connector types. Document your cable runs with lengths and routing. Write down your test results. Your future self will thank you when modifications are needed or troubleshooting becomes necessary. Trying to trace an unlabeled cable through a bundle of fifty identical-looking cables builds character, but not the enjoyable kind.

The learning curve for radio cables and connectors feels steep at first, but competence comes faster than you'd expect. Mistakes teach lessons that stick. That first connector you ruin by stripping too much insulation becomes a visceral reminder every time you pick up the stripping tool. The cable you kinked while wrestling it around a tight corner shows you why bend radius matters.

Mastering these skills opens doors. Radio systems live or die based on the quality of their cable infrastructure. Transmitters, receivers, antennas - they're all useless if the cables connecting them introduce excessive loss or create standing waves. The ability to select appropriate cables, install connectors properly, and verify system performance makes you valuable in any radio communications environment.

Start with quality components and proper tools. Cheap connectors and bargain-basement cable might save money initially, but they'll cost you time and frustration down the road. Invest in decent crimping tools, proper stripping tools, and a basic SWR meter at minimum. Learn the specifications that matter for your applications. Practice your techniques on scrap cable until they become second nature.

Radio communication rewards precision and punishes sloppiness with a clarity most fields lack. Your mistakes show up as measurable degradation in system performance. But master the fundamentals of cable and connector work, and you've built a foundation that'll serve you throughout your career. The electrons flowing through those carefully prepared connections don't care about intentions - they respond only to the reality of the physical connections you've created.